New Paragraph

EcoStill 35

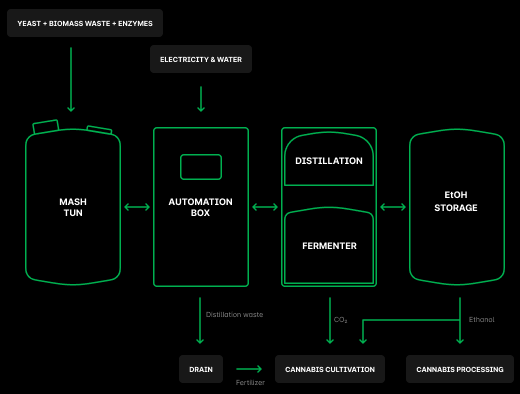

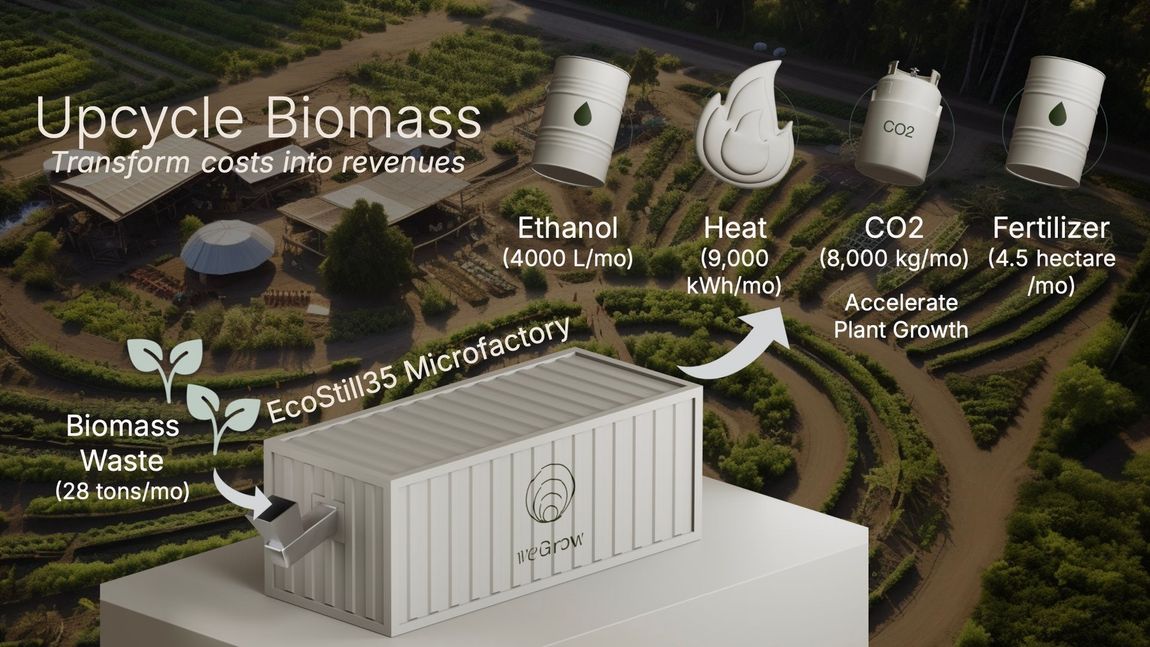

CONVERT YOUR WASTE BIOMASS TO ETHANOL, CO2, PROCESS HEAT AND FERTILIZER

Founded in 2020. Based in Berkeley, California with global operations. We develop low-impact, high-value, low-cost Eco-Industrial Solutions for the New Vitality Economy.

Introducing world’s first automated bioethanol micro-distillery.

Empowering cannabis producers with circular economy:

Decreasing financial & environmental impact and dependency upon costly third-party ethanol, CO2, fertilizer and waste disposal. For cultivators - Increasing production yield and quality for multiple revenue streams. The money saved using this system will pay itself off in 3-5 years.

Tons Disposed

28 tons / month

Disposal Savings

12-34K / Month

Ethanol Purity

70-95%

Ethanol Yield

35 gals / day

OpEx

5-7K / Month

Labor

~14hr / week

Ethanol

35% of biomass converted to high purity ethanol

CO2

Up to 18,000 lbs CO2 / month

Fertilizer

Biochar + Compost

Process Heat

35 kWh Thermal/month

A game changing production solution

BEYOND SUSTAINIBILITY

Sustainable. Circular. Regenerative.

Designed to integrate seamlessly with your cannabis operation reducing costs and impact of your operation.

INTELLIGENT

Self-Operating & Self-Cleaning.

Onboard Siemens PLC Controller directs sensors, valves and pumps to fully automate production following manual input of biomass, sugar or starch and yeast.

PRODUCT HIGHLIGHT

- Ultra-Compact

- Co-Products

- Automatic

- Self-Cleaning

- Customizable

- Full Service & Warranty

Claim resource autonomy & control

ENGAGEMENT MODEL

- Invest

- Buy

- Lease

- Partner

- Distribute

THE INNOVATIONS

Patent-pending defensible technology

Comprehensive automation system and space saving architecture.

Scalable Platform

easily configured to match your application

THE BOTTOM LINE

- Low biomass disposal costs

- Low ethanol cost

- Stable disposal and ethanol prices

- Low Maintenance & Warrantied

- E2E Management & Tech Support

- Ecologically Ethical Practice

- Regulatory & Legal Service

We offer a range of product sizes and we can design and build to you exact specifications if these offerings aren’t what you need.

| Product Specifications | |||

|---|---|---|---|

| Feature/Specification | ES 5 | ES 35 | ES 100 |

| Tons of leaves and flower Biomass disposal | 2 | 14 | 40 |

| Tons of stalks and stems biomass disposal | 2 | 14 | 40 |

| Total Biomass Waste Disposal Capacity (Tons) | 4 | 28 | 80 |

| Ethanol Produced (Gallons/Month) | 130 | 910 | 2,600 |

| Ethanol Produced (Gallons/Day) | 5 | 35 | 100 |

| CO2 for Greenhouse enrichment (tons/month) | 2.5 | 17.5 | 50 |

| Heat Generated (kWh/month) | 1,340 | 12,320 | 27,000 |

| Biochar Production (tons/month) | .13 | .9 | 2.7 |

| Operating Cost Estimates | ES5 | ES35 | ES100 |

|---|---|---|---|

| Maintenance | $250 | $1,200 | $2,000 |

| Direct Labor | $530 | $1,200 | $1,900 |

| Raw Materials total | $525 | $2,400 | $6,400 |

| Enzyme | $100 | $700 | $2,000 |

| Yeast | $175 | $1,200 | $3,400 |

| Others | $250 | $500 | $1,000 |

| Utilities | $500 | $700 | $1,200 |

| Logistics | $250 | $1,200 | $2,000 |

| Totals | $2,055 | $7,900 | $15,500 |

| Operating Cost Estimates | ES5 | ES35 | ES100 |

|---|---|---|---|

| Maintenance | $250 | $1,200 | $2,000 |

| Direct Labor | $530 | $1,200 | $1,900 |

| Raw Materials total | $525 | $2,400 | $6,400 |

| Enzyme | $100 | $700 | $2,000 |

| Yeast | $175 | $1,200 | $3,400 |

| Others | $250 | $500 | $1,000 |

| Utilities | $500 | $700 | $1,200 |

| Logistics | $250 | $1,200 | $2,000 |

| Totals | $2,055 | $7,900 | $15,500 |

Introducing world’s first zero-impact automatic bioethanol micro-distillery.

Empowering cannabis producers with profitable resource autonomy:

Decreasing financial & environmental impact of dependency upon costly third-party ethanol production/delivery. Increasing production yield and quality for multiple revenue streams.